Simply Dedicated to Custom Sheet Metal Stamping, Fabrication, Weldment, Assembly, and Surface Treatment

Product Safety Above All

Product Safety is something more than process reliability and repeatability to us. Our supplier chain covers thousands of commodities which can bring many challenges associated with a wide range of factors that may potentially affect safety risk. Therefore, Product Safety Program and APQP are combined and applied in our company to ensure the parts that we make for are up to specification and compliant to product safety. This is a vital task for the company to maintain the culture of product safety from the top management to the new recruitment.

Our Staffs Know "Our Parts Have To Be Right"

Our customer shares with us their posters, and we are authorized to use them with our logo in order to remind our staffs at EVERY level beginning from our process design to supply chain management that "Our Parts Have To Be Right" as they are parts of the commercial, public, and special mission vehicles.

Accredited To IATF-16949

Sun Strong always remembers and appreciates the assistance and onsite training which were given from one of the company's most valuable customers to our staffs and management in 2000. This incident had elevated the company to a new Level of Quality Mindset and Scope of Management through the achievement of QS-9000, and since then Sun Strong were able to upgrade themselves to TS-16949 in 2008 and IATF-16949 in 2016.

Our Parts Do Have Nothing to Hide Even We Respect their Privacy

We apply HD video capture when certain features require 100% inspection.

Almost All Customers' Requirements can be Measured, Tested and Verified In House

In-House Test Equipment

ROHS Compliance Analyzer

Chemical Composition Analyzer

Coating Thickness Analyzer

Color Analyzer

Material Hardness Analyzer

Salt Spray and Fog Chamber

Extreme Environmental Test Chamber

Full HD Inspection System

Planar Laser Inspection System

Push Pull Torque Tester

Conductivity Analyzer

Cleanliness Analyzer

CMM

And Many Others which are Necessary for Sheet Metals

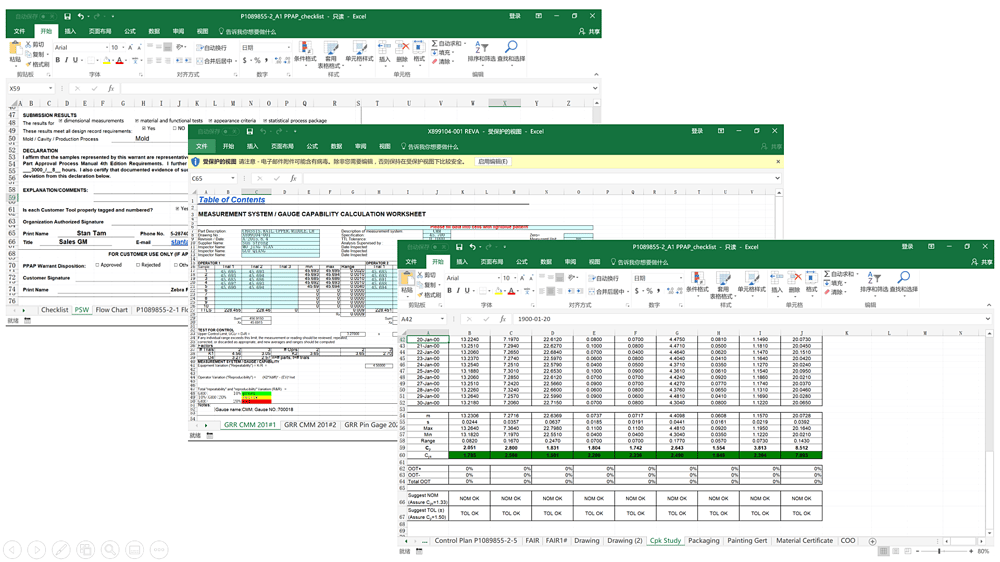

Quality Assurance Program

Sun Strong is fully accredited to ISO-9001 and IATF-16949 Quality Management System, to give our customers in commercial vehicle sector a piece of mind. Quality Assurance Program Includes APQP, PPAP, SPC, MSA, Capability and other Measurement Techniques. The relevant skills also enable the company of using statistical process control systems and mathematics data to support our customers in other industries, who also demand repeatability and safety control in their parts and products. The way we purchase and the way we produce are also the keys of the program.

PPM Performance Matters

Quality Objective is Crystal Clear Across The Company

40+ Years of Experience in Good and Bad Times

With over 40 years of solid experience in process design, manufacturing, quality assurance, logistics, international specifications and global trade practice, Sun Strong can support your custom sheet metal stamping and fabrication requirements of all types of precision sheet metal works: weldment, modules, enclosures, cabinets, chassis, frames, brackets, covers and clips. Both standard and custom types, and mostly complicated.